TRANSFORMING CONSTRUCTION

Rich Humphrey from Bentley Systems tells Andy Brown how construction can take its next step on the tech journey

“I guess the question is: when do we hit this big inflexion point? When do we cross the chasm? We’re not there yet,” says Rich Humphrey, Vice President of Product Management at Bentley Systems. Humphrey, who has been playing a role in helping to drive construction’s digital adoption for the best part of two decades, is answering where he thinks construction is on its technology journey.

"WE’RE MEETING CUSTOMERS WHERE THEY ARE TODAY BUT ENABLING THEM TO EVOLVE AT THEIR OWN PACE AND GO FULL-BLOWN DIGITAL TWIN IF THEY WANT TO”

RICH HUMPHREY, VICE PRESIDENT

OF PRODUCT MANAGEMENT AT BENTLEY SYSTEMS

The first step of this journey – and one that is increasingly being taken – is digitising paper and processes. CPM scheduling tools are much more common now, as is project management software and, to a lesser extent, mobile apps. The issue with this, says Humphrey, is that they aren’t transformative, they are, “evolving and automating what we already did with paper and Excel spreadsheets and 2D CAD with PDFs.”

Once he gets on a roll talking about technology Humphrey is the kind of character who hardly pauses for breath, such is his enthusiasm and knowledge. He believes that what will be transformative for construction is a true model that updates in real time and can be broken down into different components: in other words, a digital twin.

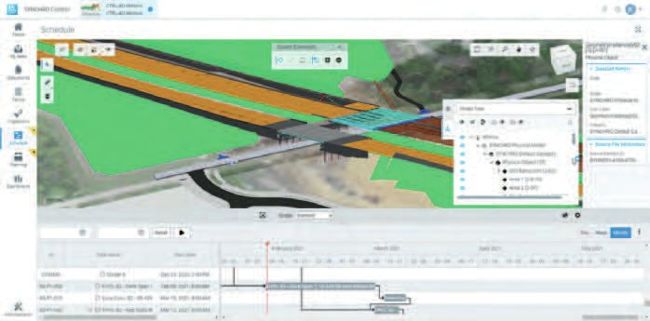

Talking about such models, he says, “the adoption is still low, but it’s the way that we’re going to create a true construction model. That’s what we’re trying to advance.” He adds that, “They start to change the way you work. When I say transformative, I think about 4D scheduling, when you add time to the model, and then you can add things that aren’t designed like staging and sequencing. “Then you can pull in reality models on top of that and run a simulation of how you’re going to build a project. You find all sorts of issues and mistakes and ways to optimise your resources. You’ll never go back to doing planning the way you did before.”

A DIGITAL TWIN OF A BRIDGE – DIGITAL TWINS ALLOW FOR A PROJECT TO BE VIRTUALLY CONSTRUCTED BEFORE ANY PHYSICAL WORK TAKES PLACE

Having the opportunity to run a simulation model before construction takes place, allowing the contractor to find mistakes before they do them in the field, could play a key role in boosting the industry’s productivity.

TURNING POINT FOR CONTRACTORS

Few in the industry would argue that construction is in need of a transformative process – almost all large projects come in over budget and late. Humphrey believes that we are at a turning point where public agencies, such as Department of Transports (DOTs) are starting to demand more transparent processes from the contractors that they award projects to.

“We need to transform our workflows so that we have more predictable project outcomes,” he says. “This will also help on the funding side, because I don’t think public agencies are going be able to fund and close the supply and demand gap that we have. We have to make infrastructure more investible to help close that gap and not just rely on public funds.

“I think we’re at the critical two years with the US DOTs [Departments of Transport] in terms of them seriously figuring out how to change how they’ve been working and what their expectations are with contractors.”

Bentley’s key weapon in the battle to transform construction’s digital journey is Synchro. There’s a few ways to describe Synchro, depending on just how technical you want to get, but the top-line version is that it is the company’s construction management platform for the full life cycle of a programme; from planning all the way through to execution and handover. It is part of Bentley’s larger idea of an infrastructure cloud that manages data through the life cycle of a project.

BENTLEY SAYS THAT SYNCHRO ALLOWS THOSE IN CONSTRUCTION TO ACCESS, MANAGE, COLLABORATE, AND ANALYSE PROJECT DATA ALL IN ONE PLACE

Humphrey says what’s key about Synchro is that it meets customers where they want to be. It can do relatively straightforward tasks like use AI to capture and index pictures, manage PDFs, do form-based workflows, document controls and project management or allow them to create a digital twin. “We’re meeting customers where they are today but enabling them to evolve at their own pace and go full-blown digital twin if they want to. They like it because it’s future proofed,” he says. “When they get contracts that require that, they don’t have to change systems. That’s been our approach to helping the industry evolve.”

COLLABORATION

One of the ways that Bentley is working with the industry is through a ‘collaboration initiative’ with engineering firm WSB to encourage civil infrastructure owners and contractors to adopt and use infrastructure digital twins. WSB has launched a new digital construction management solution and advisory service, based on Synchro, to help the civil infrastructure market overcome the challenges of adopting model-based digital workflows and leveraging the power of digital twins. The company is the first to join the Bentley Digital Integrator Program for construction. Construction work is often based on 2D drawings, spreadsheets, and document-based workflows that can result in errors, waste and rework that cause most projects to be over budget and schedule. The collaboration between Bentley and WSB aims to change this and help firms adopt technology and digital delivery. “WSB are involved with a lot of contractors doing complex design-build projects. They’ve decided to start a new business to help drive the adoption of model-based workflows, leveraging Synchro. They’re providing a whole new service to the industry,” explains Humphrey. “That model of us partnering with an engineering firm to help owners and contractors cross the chasm in terms of digital delivery is another important step to help the industry move forward.” All connected with the growing sector of construction technology want to see it develop and for adoption to increase.

Humphrey says that, in a few years’ time, he hopes that project management tools and basic field capture is common, that everyone has reached that stage of the evolution and are now thinking about how to get into a position where they are able to progress to digital twins. “The digital twin is the hub for how you access, manage and pull all different technologies together,” he says. “It’s not just about construction execution. It’s about how we deliver for owners and the public who rely on infrastructure. How do we connect the entire lifecycle better than in the silos like we see today?” Getting to that point will no doubt be more challenging and complex than automating some processes and having basic field capture as standard, but the opportunities that it will bring are also much bigger – perhaps even transformational. CT